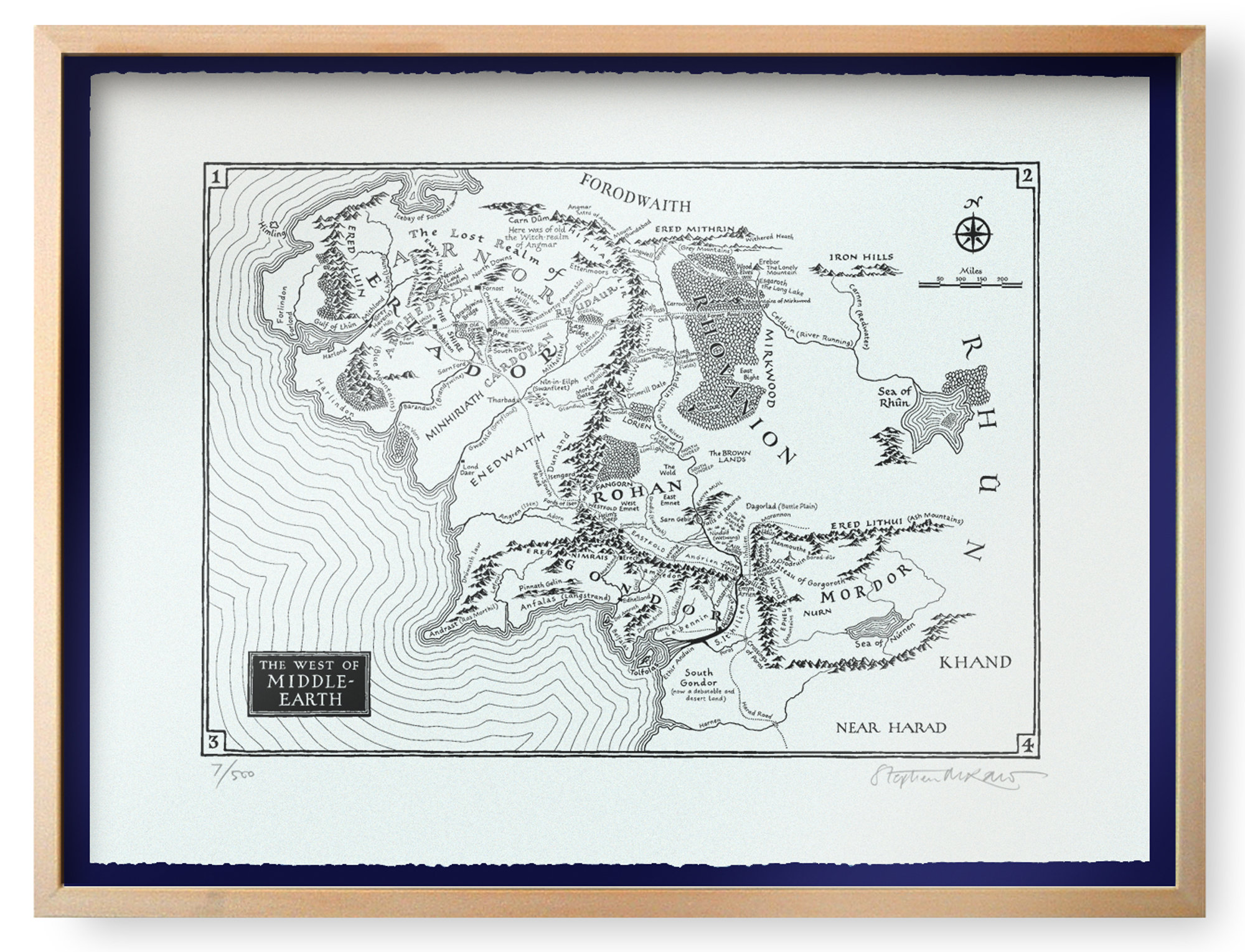

Lord of the Rings Shire Maps

It pays to have been around a long time

CLIENT:

Stephen Raw (artist)

PROJECT:

Limited Edition set of Lord Of The Rings Shire maps.

BRIEF:

Produce a limited edition run of 500 copies of each of 3 large maps with a finished size of 560mm x 760mm onto material provided by the client.

BACKGROUND:

The client partly owned the rights to the three large maps he had hand drawn and which featured in the latest published edition of the famous literary work by the author J R R Tolkien.

The Tolkien Estate gave the artist permission to sell a limited edition run of each of the 3 maps.

Stephen wanted to reproduce them on a traditional hand-made 100% cotton rag paper with deckle (uneven) edges.

He sourced the very expensive materials from Italy and had unsuccessfully attempted to get them printed using a plan printing process.

Albeit this produced an accurate image straight from the original, problems with using this method included the pigment being unable to penetrate the undulations in the uneven surface of the material.

Other issues were guaranteeing the light fastness of the pigment and maintaining the position of the image in the centre of the material because the deckle edges of the paper did not allow any form of alignment.

Solution:

Our first task was to ensure, that whatever reproduction method we used, it was faithful to the originals. In this respect, plan printing had one minor advantage, in that it was a direct process, original to copy – no steps in between.

The large originals created another problem to be solved.

Creative Consortium regularly collaborated with a specialst reprographics company which had not scrapped it’s high-end large-format drum scanner(within the industry, a piece of technology now redundant, and effectively a huge paperweight, due to the proliferation of digital source media).

After being briefed on our proposed production method, the map originals were scanned at over 12,000 dpi by an operator with vast experience and output directly to lith film. In each case, the film was carefully examined for suitable exposure, any aberrations and for its faithful reproduction of the originals. Once the films were quality checked and approved by us we moved on to the next stage – printing.

Our ‘list’ of resources included a “traditional” printing support company with an ultra-large flat-bed offset litho proofing press.

Normally a proofing press would be used for producing 10-12 sheets of a potentially longer print run on other machines, but we persuaded our colleagues at the suppliers to use this method for the 500 run of each map.

The machine could exert several pounds of pressure during the printing process (much more than a normal printing press) and, therefore, overcome the problem of fixing the ink to the rough paper surface. Another advantage of this method was that we could source a small quantity of specialist light-fast ink cost effectively.

Each individual sheet of material was hand-fed into the press using locked-down grip and side-lay markers to position the image correctly in the centre. And, unlike a large printing press, the operator of a proofing press can easily stop after one sheet of paper has been printed. This meant each and every sheet printed could be easily checked for quality.

Results: